Flats

The standard theatrical unit has long been the flat. These are what we use to create and represent walls or other vertical surfaces on stage.

Flats are an open frame made of either wood or metal, covered with a lightweight material like fabric, wood, plastics, or plexiglass. In the earlier days of theatre, frames were wood and were covered with painted fabric. More recently, frames have been made of wood or metal tubing and coverings have been thin plywood.

To this day, there are still two (2) styles of theatrical flats: the soft-covered (Standard) flat and the hard-covered (Hollywood or Studio) flat.

Standard flat

The standard flat, also called a "theatre" or "Broadway" flat, is a wooden frame made of 1x3 or 1x4 dimensional lumber (often pine).

Standard flats are constructed with the wood flat or "on face." This means that the frame pieces are laid flat (or their widest side) to the eventual surface of the unit, and assembled using butt joints held together with wide crown staples, corner blocks and keystones (pre-cut 1/4 ply pieces that add stability and keep the flat square).

The surface of the flat is a covering of canvas or muslin fabric. The fabric is laid on the frame smoothly but not tightly. It is then stapled to the frame along the inside edge about every 6" to 8". The fabric flaps are folded back and a slightly diluted coat of white glue is painted on the frame. Fold the flaps back and go over it with a wet sponge or paintbrush. It is a messy process! After the glue is dry, extra fabric is cut off using a utility knife, also called a box cutter.

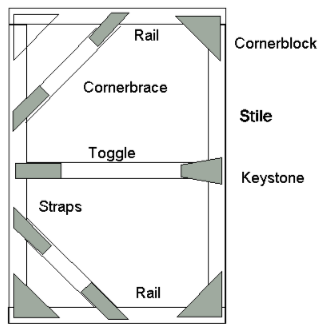

Important Parts:

Rails - the top and bottom supports, create the width of the flat.

Stiles - the vertical supports, create the height of the flat. Because they butt-up to the rails and sit inside of them, you need to subtract the combined width of the rails when determining the length of the stiles.

-

For example - if you want to make an 8'-0" tall flat out of 1x4, your rails would need to be cut to 7'-5"

-

- 1x4 is actually 3/4" x 3-1/2"

- 3-1/2" + 3-1/2" = 7" (width of two rails)

- 8'-0" - 7" = 7'-5"

-

Toggles - interior supports that keep the stiles from flexing or bowing in. As a general rule, you need a minimum of one toggle for every 4' of height.

Corner blocks - the mechanical fasteners that hold the frame together. Corner blocks are generally right triangles 10"x10" that are made from 1/4" plywood. For stability, the surface wood grain should be across the joint at perpendicular or diagonal angles, NOT parallel to it.

Straps & Keystones - are either rectangular (straps) or "keystone" shaped and used to attach the toggles to the stiles. The keystone shape is slightly stronger but takes longer to make. The keystone would be about 3 1/2"x7"x2 1/2". The rectangular strap would be about 2 1/2 to 3"x7".

Corner blocks and keystones are secured using an 11 nail/staple pattern for corner-blocks, and a 7 to 10 nail/staple pattern depending on fastener and usage.

Standard fasteners are either pneumatic staples and glue, or occasionally 3/4" screws. Screws are quick and allow easy disassembly. Staples by themselves are not strong enough, but with glue are very fast and permanent.

Hollywood or Studio flat

Hard-covered flat that is made with the frame boards "on edge" rather than flat. 1x4 and 2x4 lumber are most common. 1x3 is generally enough if it is good quality, and can help reduce the weight of the units, as well as significantly reducing required storage space.

Instead of canvas or muslin, the frame is covered (or faced) with 1/8" or 1/4" plywood or lauan. Lauan is much weaker than plywood, but it is lighter and the surface is much smoother.

The construction of a hard-flat is simpler than a standard flat. The frame is simply screwed together like a box, and the surface nailed, stapled or screwed on. It doesn't need corner blocks, keystones, or straps, as the hard-cover is way more structural than fabric and will keep the framing stable and square.

Otherwise, Hollywood flats have all the same parts as a standard flat: rails, stiles, and toggles. Excess wood from the facing can be removed by using a router with a flush trim bit.

The typical fasteners used are drywall screws between 2" and 3" in length for the frame, and either staples, nails, or short screws to attach the facing to the frame.

Advantages and disadvantages

Standard flats are much lighter than a similar size Hollywood. One person can even handle a flat by themselves. They are also somewhat cheaper in materials too, as canvas is cheaper per square foot that plywood. Canvas also gives a very good painting surface without obvious grain to fight. Since they only take about an inch to store, you can store a number in a fairly thin space.

However standard flats are less rigid, so they require stiffeners and bracing to support walls of them, and the canvas can flap if the flat is bumped or a door in the wall is slammed. They take longer to build, and are fussier to construct. It is easy to get them out of square.

Hollywoods flats are easier to assemble into corners, as they can be nailed or screwed and do not require extra pieces in order to keep their rigidity. Hollywoods are also easier to get square, somewhat easier to build, and don't "flop in the breeze" when someone walks past. They are easy to join together with clamps or screws, and are easy to paint, as you can use as roller instead of a brush.

However they are much heavier, often require multiple people per flat to move, and you have to pay some attention to the seams in the plywood, which otherwise show every 4 x 8 feet.

Securing Flats

Let's face it, falling scenery is bad scenery. So whatever we build, we need it to stand upright.

With Hollywood flats and your own stage deck, one way you can secure the flat upright is by attaching the bottom rail of the flat directly to the deck or platform it is on with long screws.

Another common way to secure a flat is through a piece called a jack brace.

Jack braces are wooden or metal, triangular supports that are used to hold the flat in an upright position. They are attached to either the toggles or the stiles and the floor. The brace must either be screwed into the floor or have a stage weight or sandbag added in order to counter-balance the flat and to stabilize it.